Events

Dynamic

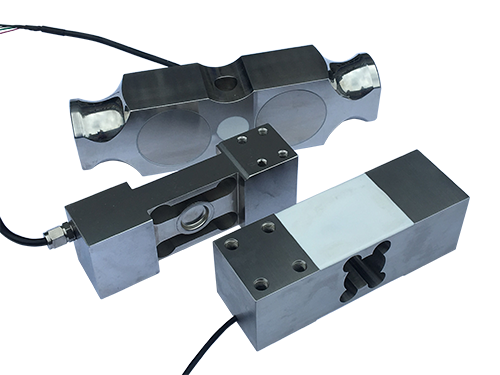

Weighing load cell general structure calculation

This article is based on the load cell to help designers. Its in-depth analysis to derive some formulas, these formulas to calculate some load cell size, and provide the required output, which also describes the various error sources and design recommendations.

Paste-type resistance strain gauges are widely used in today's high-precision force measurement and load cell manufacturing. This article is to help designers to calculate the load cell size, which is only required to obtain the output of thorough preparation. Designers can either use the finite element analysis by computer program (if possible) to determine the load cell required size, or use of this formula provided in this size. Stress formula selected from a very good book - the stress and strain formula (see reference [1]). In addition to formula assembly, the paper also discusses possible sources of error and design recommendations, the error sources of information is mainly based on the author's experience. Described in the text is not related to the load cell for patent investigation, discussed in considering the design for the production or the market before, it is necessary to make a few inquiries.

These assumptions lead by some formula, in addition to the characteristics of resistance strain gauges, stress form, materials and machining characteristics of the deviation will lead to a certain calculation errors. Before load cell in volume manufacturing, it should create several prototype assembly, test and calibration.

In some industries, such as the aerospace industry may need only one load cell, to determine its non-linearity, repeatability and hysteresis errors, etc., before use, calibrated is important. When the computer is used in data processing, nonlinear, zero drift and sensitivity change is very easy to amendment. If the load cell used to go through the intense temperature changes and external impact of additional load, we should test and measure the amount of impact caused by these errors. If a part of the structure (such as connectors, pins, struts) used to measure or to be used as a load cell, the calibration and testing is particularly important.

Load cell design includes many aspects, not discussed here for its manufacturing, for example, the need for resistance strain gages installed comprehensive understanding of technical knowledge, some of the resistance strain gage manufacturer provides technical information, while also providing resistance strain gages installed the classification.

In the past decade, computer technology has changed the load cell design, manufacturing and recording, for example, resistance strain gages were installed, all of the load cell has an original unbalanced (when there is no load time , the output signal is also present). Zero adjustment resistors are usually used in commercial load cell in order to eliminate this imbalance. The use of computer programs, data can easily be zero imbalance removed. In addition to the zero adjustment resistor, the precision of the commercial load cell installed in a lot of resistance, easy to compensate for temperature effects such as zero point and sensitivity. If the recorded data at the same time, the load cell temperature was measured, and when the load cell is calibrated, the error caused by temperature has been measured, then the use of computer programs should be revised final data. Commercial load cell manufacturers do not provide for the computer to correct an imbalance or temperature of the original data, because they do not want to limit the market. Commercial load cell zero balance and not to install temperature compensation resistor will save a lot of money, especially when high demand is more effective.

Paste-type resistance strain gauges are widely used in today's high-precision force measurement and load cell manufacturing. This article is to help designers to calculate the load cell size, which is only required to obtain the output of thorough preparation. Designers can either use the finite element analysis by computer program (if possible) to determine the load cell required size, or use of this formula provided in this size. Stress formula selected from a very good book - the stress and strain formula (see reference [1]). In addition to formula assembly, the paper also discusses possible sources of error and design recommendations, the error sources of information is mainly based on the author's experience. Described in the text is not related to the load cell for patent investigation, discussed in considering the design for the production or the market before, it is necessary to make a few inquiries.

These assumptions lead by some formula, in addition to the characteristics of resistance strain gauges, stress form, materials and machining characteristics of the deviation will lead to a certain calculation errors. Before load cell in volume manufacturing, it should create several prototype assembly, test and calibration.

In some industries, such as the aerospace industry may need only one load cell, to determine its non-linearity, repeatability and hysteresis errors, etc., before use, calibrated is important. When the computer is used in data processing, nonlinear, zero drift and sensitivity change is very easy to amendment. If the load cell used to go through the intense temperature changes and external impact of additional load, we should test and measure the amount of impact caused by these errors. If a part of the structure (such as connectors, pins, struts) used to measure or to be used as a load cell, the calibration and testing is particularly important.

Load cell design includes many aspects, not discussed here for its manufacturing, for example, the need for resistance strain gages installed comprehensive understanding of technical knowledge, some of the resistance strain gage manufacturer provides technical information, while also providing resistance strain gages installed the classification.

In the past decade, computer technology has changed the load cell design, manufacturing and recording, for example, resistance strain gages were installed, all of the load cell has an original unbalanced (when there is no load time , the output signal is also present). Zero adjustment resistors are usually used in commercial load cell in order to eliminate this imbalance. The use of computer programs, data can easily be zero imbalance removed. In addition to the zero adjustment resistor, the precision of the commercial load cell installed in a lot of resistance, easy to compensate for temperature effects such as zero point and sensitivity. If the recorded data at the same time, the load cell temperature was measured, and when the load cell is calibrated, the error caused by temperature has been measured, then the use of computer programs should be revised final data. Commercial load cell manufacturers do not provide for the computer to correct an imbalance or temperature of the original data, because they do not want to limit the market. Commercial load cell zero balance and not to install temperature compensation resistor will save a lot of money, especially when high demand is more effective.