Electronic weighing load cell has been hailed as the heart, its performance largely determines the electronic weighing accuracy and stability. In the design of electronic weighing, the often encountered problem of how to select the sensor. Actually load cell is to turn quality signal into electrical signal output. Selection of sensors must first consider the actual working environment, which is essential for the correct selection, it is related to the sensor can work as well as its safety and service life, and the whole long-term reliability of electronic scales. The following should be noted that when used:

First, the impact of environment on the sensor are the following:

1, high-temperature environment on the sensor caused by melting sealing materials and solder joints, elastic stress and strain gauge structural changes and other issues. For high-temperature environment, anti-high temperature sensor is often used; In addition, the harsh situation must equip with insulation, water-cooled or air-cooled and other devices.

2, dust, heat and humidity on the sensor causing a greater impact. In this environment should be used high airtight sensor. Different sensors, its different from the way its seal method is different, and its enclosed nature having significant differences. Common seal with sealant filling or coating; mechanical fastening rubber seal; welding (laser welding, TIG welding, plasma welding, etc.) and nitrogen vacuum seal.

From the sealing effect, the welded seal is the best, filling sealant for the poor. For the interior clean, dry working environment sensor, choose the sensor filling sealant, and for some moisture, dust the work environment of high sensor, should be selected diaphragm or diaphragm seal welded heat seal sets, nitrogen vacuum sensor.

3, the higher the corrosive environment, such as moisture, acidity of the sensors and accessories causing damage to elastomers, corrosion and other effects should be chosen over the outer surface of the elastomeric spray or stainless steel and stainless steel housing, good corrosion resistance and airtight good sensor.

4, the electromagnetic field of the sensor output signal interference. In this case, the shielding of the sensor should be strictly checked to see whether it has good resistance to electromagnetic interference.

5, flammable, explosive not only for the thoroughness of the sensor caused the damage, and returned to the other equipment and cause a great threat to personal safety. Therefore, flammable, explosive working environment of the sensor on the explosion of a higher performance requirements, it must use explosion-proof sensor, this sensor is sealed housing not only consider the closed nature, but also take into account the explosion strength, and the cable leads to the first waterproof, moisture-proof, explosion-proof and so on.

Second, focus on the number and range of sensor

Number of sensors are selected according to the use of electronic weighing, scale body needs to support the points (support points should be based on the geometric center of gravity to balance the body and the actual center of gravity to determine the principle of coincidence) may be. In general, there are several strong point scale body on the selection of a few sensors, but for some special scale body, such as electronic crane scale can only use a sensor, some combination of electrical and mechanical scales should be selected based on the actual situation to determine the sensor the number.

Sensor range selection can be based on the largest scale weight value, choose the number of sensors, body weight scale, the maximum possible partial load and dynamic load factors such as comprehensive evaluation to determine. In theory, the closer the sensor range of the load assigned to each sensor, the higher the accuracy of weighing. However, in actual use, due to increase in the load sensor is called an object in addition, there are also scale body weight, tare weight, partial load and vibration shock loads, so use the sensor range, you should consider many factors, to ensure and life safety sensors.

※ sensor range is calculated empirical formula is fully taken into account the various factors affecting the scale body, after a lot of validation and determined. Formula is as follows:

C = K0K1K2K3 (Wmax + W) / N

C-single sensor rated range; W-scale body weight; Wmax-the maximum weight of object; N-scale support points; K0-insurance factor, the general value between 1.2 to 1.3; K1-impact factor; K1 value is determined based on the following conditions: a) When N sensors even under load, and in the absence of vibration, shock-free working conditions, K1 = 1.1-1.3; b) When the occasional shock and vibration the situation, K1 = 1.3-1.5; c) When in a repetitive shock and vibration conditions of dynamic weighing, K1 = 1.7; When N sensors by uneven load, partial load is likely to form under the maximum load can be multiplied by the factor; K2- scale body's center of gravity shift factor; K3-pressure coefficient.

For example: a 30t electronic truck scale, the largest weighing Wmax is 30t, scale body weight W is 1.9t, designed with four QS-A sensor, according to the prevailing circumstances, select the insurance coefficient K0 = 1.25, the impact factor K1 = 1.2, the center of gravity offset coefficient K2 = 1.03, pressure coefficient K3 = 1.02, test to determine the sensor's range.

Solution: According to the sensor range formula: C = K0 K1 K2 K3 (Wmax + W) / N

We can see: C = 1.25 × 1.2 × 1.03 × 1.02 × (30 +1.9) / 4 = 12.57t

Therefore, the choice of range for the 15t sensor (QS-A type of sensor range to only 10t, 15t, 20t, 25t, 30t, 40t, 50t, etc., unless a special order).

According to experience, the general sensor work in its 30% to 70% range, except for some in the course of the scales there is a big impact, such as dynamic rail scale, dynamic truck scale, steel scales, etc., in the selection of sensors, to expand its range, the sensor operates in the range 20% to 40%, so that the sensor weighing reserves increased to ensure the safety and life, to avoid overloading.

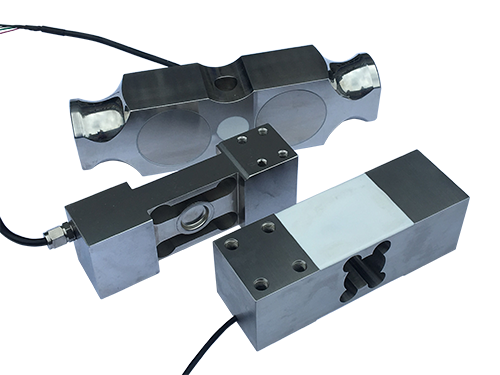

Third, consider the application of various types of sensors

Sensor type depends on the weighing type and installation space, to ensure proper installation, safe and reliable weighing; on the other hand, consider the sensor manufacturer's recommendations. Sensor manufacturers are generally based on the force sensor, performance indicators, the installation form, structure type, elastomer materials such as the scope of the sensor characteristics, such as aluminum single point cantilever sensor for pricing scales, platform scales, counter scales, etc.; steel cantilever sensors for hopper scale, belt scale, sorting scales, etc.; steel bridge sensor for track scale, truck scale, crown block scales, etc.; column sensor for truck scale, dynamic railroad scale , fixed the dynamic axle load scales, hopper scales and other large tonnage. Therefore, weighing sensor manufacturers should adopt the recommendation of the manufacturer.